About SHANBEI technology

Focus on the development of Marine automation electronic equipment and systems

Ningbo SHANBEI Technology Co.,Ltd founded in April 2020, is a national high-tech enterprise founded by high-level talents in Ningbo City. The company has passed the quality management system certification of China Classification Society and is a member of China Ship and Ocean Engineering Industry Data Union. Since its inception, the company has focused on the development of Marine automation electronic equipment and systems.

Quality assurance

Ningbo SHANBEI Technology Co., Ltd. has passed the GB/T19001-2016/ISO9001:2015 certification, reaching the high quality standard. We have established a quality management system that covers all activities. We pay special attention to the company's internal product production management, to continue to provide customers with high quality products is our consistent pursuit.

In order to meet this high standard, we carry out a series of interlock test projects, starting from concept design, through production process testing, final machine performance testing, and system burn-in testing.

In order to meet this high standard, we carry out a series of interlock test projects, starting from concept design, through production process testing, final machine performance testing, and system burn-in testing.

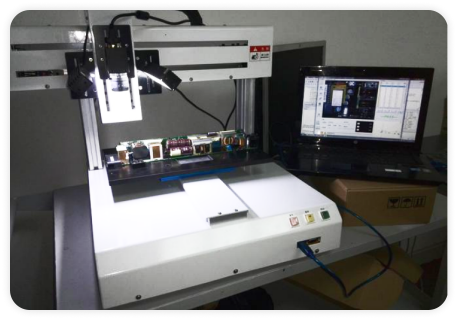

AOI test

Each finished component goes through an automated optical inspection (AOI system), where some deviations that cannot be detected by the naked eye are found and the faulty modules are screened out. We designed a special PCB test fixture, with the pre-designed test point on the PCB, to check the PCB welding quality, assembly quality, to ensure a comprehensive functional test of the product.

Although we have established a sound production process for each product, modules still occasionally have deviations, such as soldering or part errors, and this deviation cannot be permanently eliminated. Each critical component, such as the PCB, is carefully checked at the beginning of assembly to ensure that questionable components can be screened out.

Although we have established a sound production process for each product, modules still occasionally have deviations, such as soldering or part errors, and this deviation cannot be permanently eliminated. Each critical component, such as the PCB, is carefully checked at the beginning of assembly to ensure that questionable components can be screened out.

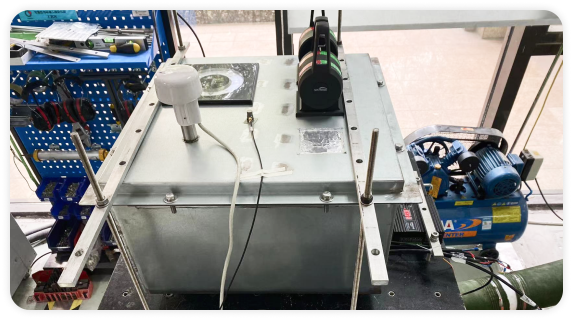

Environmental and electromagnetic compatibility testing

Programmable environmental test equipment can simulate the extreme environment in which the product works, and the function of the product under test can be checked under predetermined high and low temperature conditions. Most modules operate at temperatures between -30 ° C and 70 ° C or between 0 ° C and 50 ° C. For products used outside the cabin, tests can be carried out in a daylight simulator to detect the effect of solar radiation on the product through high doses of ultraviolet light.

Aging test

To ensure the longevity and reliability of our products, many components and systems undergo long-term testing after final assembly. The test facility built for this purpose simulates actual load use. As a result, errors that may occur during installation or operation can be identified early and corrected in advance. This process ensures that only fully functional products leave the factory.